Aluminium bending

Often a profile contains all kinds of built-in functionalities, such as click connections, screw channels and cooling fins. The bending process is characterized by stretching and compression, which may cause the complex cross-section to deform and important functions to be lost. We ensure that this deformation is kept to a minimum and that the functionalities are retained, even in the bend.

Curved aluminum profiles also have an aesthetic function, where great value is placed on surface quality. Attention to the process and use of special tools guarantee maximum surface protection.

In order to be able to deliver the best quality, Kersten has modern and advanced bending machines. Our team of skilled staff bend and process the aluminium in specially equipped non-ferrous areas. We advise you on the bendability as early as the design process of an extrusion. Kersten has modern bending and processing machines and a team of skilled employees. Aluminium profiles are bent, sawn to size and mechanically processed in a separate, clean environment. This enables us to deliver your semi-finished product ready for assembly.

The most suitable technique depends on several factors. These include the cross-section of the profile (the wall thickness and the various functions), the desired radius, the bending direction (over the strong x-x axis or the weak y-y axis), the alloy and the hardness state of the material.

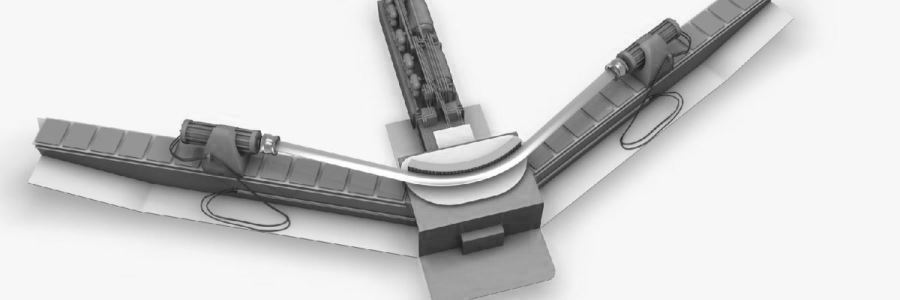

There are several methods of bending aluminum. Kersten carries out the following bending techniques:

Roll bending/rolling

In many cases, roll bending is the most flexible and cost-efficient bending method. It is an ideal technique for (large) profiles and for different radii and complex cross-sections. Roll bending greatly improves the properties and structure of the aluminum. In addition, the bending machine does not need to be converted if a different radius needs to be bent. With this process an overlength is required that can be removed afterwards if desired. The overlength can be limited by a smart material arrangement. We will be happy to advise you on this.

The profile is guided along three adjustable rolls and gradually - thus controlled - bent into the desired radius. Standard norm profiles are bent with tools that are often already available. In addition, we manufacture client-specific tools in our in-house tool shop.

Over the years Kersten has specialised in 3D bending. In addition to two-dimensional bending, a third dimension can be applied in the same roll processing.

Aluminium stretch bending

Stretch bending originated in the aviation industry, but is currently also widely used for architectural applications. It is a very precise bending method whereby the material surface remains in perfect condition and the cross-section is minimally deformed. It is ideal, for example, for aluminum facade profiles and aerofoils where the visual aspect of the application is very important.

With stretch bending the profile is firmly clamped at both ends. The machine applies tension to the profile and then pulls it around a bending tool. The material does not come into contact with the machine so the surface of the material remains in perfect condition. In addition, cross-sectional distortion is kept to a minimum due to the constant tension on the profile.

Mandrel bending

When bending a relatively thin-walled profile in a very small radius, the risk of cracks and buckling increases. To prevent this, the profile can be bent by means of mandrel bending.

The mandrel bending process is accurate, fast and delivers consistent quality. It is extremely suitable for medium and large series.